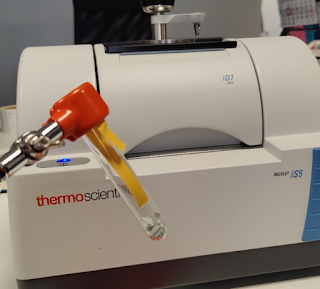

photo by PLACOMA Sp. z o.o. Sp.k.

Good practices and investments related to Cleaner Production

Example No. 47

Reducing the amount of plastic waste generated by modifying the storage procedure

Company:

PLACOMA Sp. z o.o. Sp.k., Wrocław

Industry branch: plastics

Main products: sale of recycled thermoplastic products (milled and regranulated materials), consulting, testing of materials

Resources in question:

- Secondary raw materials

- Waste

(cost-free measure, requiring only a small amount of additional work)

Before sending a shipment of granulated material to the recipient, it is necessary to carry out tests on the quality of the raw material, taken from each big-bag. These tests are necessary to prevent a semi-truck with material from being turned back after traveling a few hundred or even a few thousand kilometers due to the quality that is unacceptable for the recipient. Taking and storing samples for testing is also important in case a customer makes a complaint. Prior to the implementation of this project, the company used to take a sample of about 2 kg of material from each ton, which after testing was no longer usable and became waste.

Obtained benefits and effects of the implementation:

- Minimized waste generated during testing:

- it was planned in the project that the introduction of the aforementioned change would lead to a reduction in the amount of waste generated from supply quality control samples by at least 2 Mg/year

- in practice, the reduction in the amount of waste in 2021, compared to 2020, was as much as 2.5 Mg, despite the doubling of sales (and the amount of associated sampling for quality testing) during this time. Thus, benefits far exceeding assumptions have been achieved, as the change described here has generated about 70% less waste than would have been generated without it

- Reduction in storage space occupied by samples (no need to rent an additional warehouse)

- Lower disposal and transportation costs

- Savings: about PLN 9,000/year

- Report on the Cleaner Production Project No. 3ind.754, developed within the framework of the Cleaner Production Academy at Placoma Sp. z o.o. Sp. k.: "Minimizing plastic waste by modifying the warehouse procedure and introducing record-keeping"

- Materials (including photos) submitted by Placoma Sp. z o.o. Sp. k.

Polish version:

0 komentarze :

Prześlij komentarz